home |

electronics |

toolbox |

science club |

tuxtalk |

photos |

e-cards |

online-shop

Content:

By Guido Socher

<guido_at_tuxgraphics_org>

|

An ethernet weather station

![[Illustration]](../../common/images2/article07041/eth_weather_st_lcd_title.jpg)

Abstract:

Using an add-on card to the already existing avr ethernet board

we build a weather station. That is: A weather station with a

build-in webserver. The related articles which describe how to

build the AVR web server are here:

- An AVR

microcontroller based Ethernet device

- HTTP/TCP with an

atmega88 microcontroller (AVR web server)

The components for building this weather station

can be ordered from http://shop.tuxgraphics.org

The system is modular. You can either build a pure Ethenet weather station

or an Ethenet weather station with an additional local LCD display.

_________________ _________________ _________________

|

Sensors

My original plan was to have sensors for temperature, air

pressure and wind. I started a prototype and it worked very well

except for the wind measurement part.

I have written a separate article about it:

wind-vane-ver01.shtml. I plan to improve the wind

measurement hardware and add it at a later point in time.

For now the weather station has 2 temperature sensors and an

air pressure sensor. It works reliable and precise even after

several month of testing.

For the sensors we will use:

- For temperature measurements: LM335. This sensor is cheap

and has a linear curve over a wide temperature range.

This will give us very accurate temperature

readings over a wide range. The accuracy will be almost constant over

the whole range.

- A Motorola/Freescale MPX4115A absolute air pressure

sensor. This sensor is already calibrated at production time.

The MPX4115A is not made for

out-door use but that is not a problem. The circuit can be in

a save and dry location inside the house as the air pressure

is exactly the same inside and outside the house.

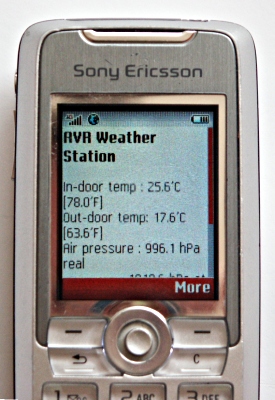

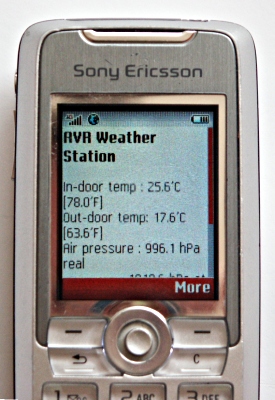

The Ethenet Weather Station as seen from a Mobile Phone

|

What's the weather at home?

You can connect it straight to the Internet by enabling port forwarding

in your DSL router. There is however a security issue with such a

straight forward solution. How to manage security and make it really secure

is described in the Using

the AVR microcontroller based web server article (available via the

tuxgraphics electronics section http://tuxgraphics.org/electronics/).

The analog to digital converter (ADC) of the AVR

The atmega88/168 has one build in ADC and a multiplexer which

allows us to select the pin on the chip where the voltage should be

measured. In other words even though there is just one ADC it

appears as if it had several ADCs. The one ADC can measure

the voltage on several pins quickly after each other. It has

also an internal reference of 1.1V. The 1.1V correspond to an ADC

reading of 1023 and 0V to an ADC reading of 0. The measured

voltage is therefore:

ADCreading

U= ---------- * 1.1V

1024

If we now look at the specification of our sensors we will see

that the range we want to measure does not correspond to

0-1.1V. We could just add a voltage divider (two resistors) to

reduce the max. voltage to 1.1V but then we will loose accuracy

as this will map the interesting range to just a few ADC

values and we will never use the full range from 0-1023.

The solution is a differential amplifier. With such an

amplifier we can map e.g a range from 3.6V to 4.15V into

0-1.1V:

Mapping of a voltage range into the ADC input range from

0-1.1V

Differential amplifiers

An easy way to build such a differential amplifier is to use

two transistors.

The problem is that this circuit has a temperature dependent

amplification factor. This is even the case if we use

additional resistors for degenerative feedback because the

amplification factor of this circuit is too low. We would need

to add more transistors.

The most common solution to the problem is an operational

amplifier. Here the amplification factor can be made dependent only

on external resistors and therefore temperature

independent.

A differential amplifier with adjustable gain based on an

operational amplifier.

Most operational amplifiers need +12 and -12 supply voltage and

that is not really usable here. We would like to have a single

exact +5V power source as the air pressure sensor needs exactly

5V. Fortunately there are some special operational amplifiers

which can work from a single power supply and still work with

voltages as low as 5V. The TLC272 is such an amplifier and that

is what we will use here.

The weather station circuit diagram (add-on board)

The circuit diagram below shows the circuit diagram of just the

add-on sensor board. It connects via CONN2 to a any tuxgraphics avr ethernet board.

Click on the picture to get a high resolution PDF

drawing.

The TLC272 is a dual op-amp. For 3 sensors we need therefore two

TLC272 and we could actually connect 4 sensors. CONN3 is

therefore available for you to put any other additional sensor.

You can e.g connect a Honeywell HIH-4000 humidity sensor. This humidity

sensor can however also be connected directly via a voltage divider

to the adc. It's just an idea. At the moment the humidity sensor is

not part of this software/solution.

If you don't want to use the extra connector then insert a wire

bridge instead of R14 and R19. All other resistors around that operational

amplifier can then be left open.

R27 is dependent on the altitude where you are. For 0-400m above

sea level you should use 5.6K and for 400-1000m 18K above 1000m

you should remove R27 and much higher you will have to change

R24. This because the air pressure is very dependent on the

altitude.

The circuit has an on-board voltage regulator because it is

important to have a clean and very stable supply voltage to get

exact sensor readings. The 4 analog output lines (CONN2)

connect then to the ADC channels ADC0-ADC3 on the avr webserver

board.

If you use the same power source for this add-on sensor board

and the avr webserver then you should make sure you connect GND

only once to avoid ground loops (CONN2 has also a GND pin).

Ground loops cause the circuit to be sensitive to magnetic

fields (transformers). If you use e.g a 7.5V power supply then

you connect the +7.5V to both the avr webserver board and the

add-on sensor board but you connect the GND of the power supply

only to the avr webserver board and the add-on sensor board

gets it's GND connection via the GND pin on connector CONN2.

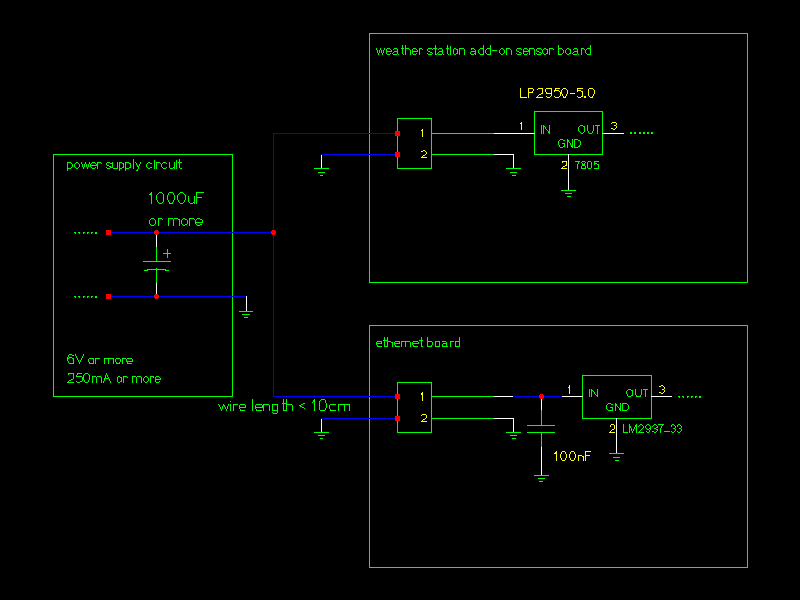

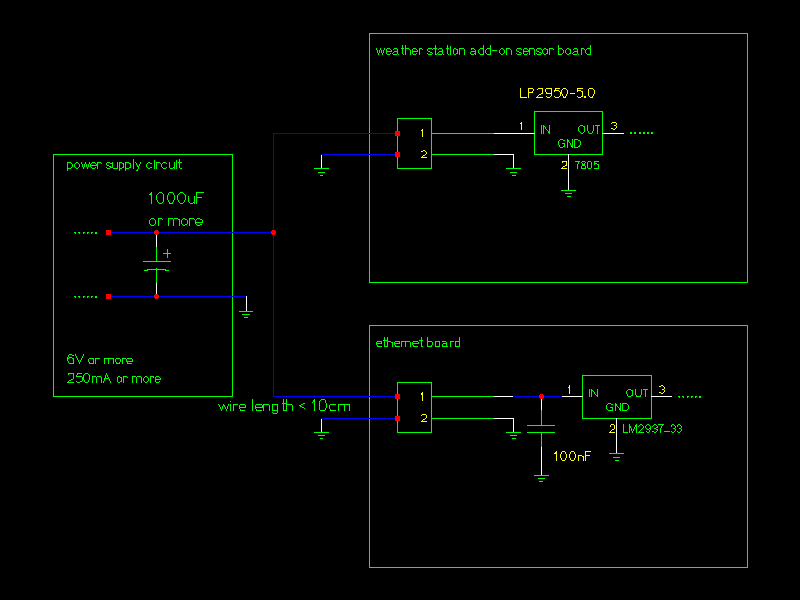

Power supply requirements

Ethernet works reliably over 100m long cables. It needs therefore

a bit of power. The main power consumer is the ethernet chip.

The rest of the circuit needs so much less that it

can be totally neglected in any power consumption calculations.

Click on the picture to get a high resolution PDF

drawing.

The ethernet chip needs in average 150-180mA at

3.3V. This is however an average. At the moment of packet processing

it needs twice as much for a few milliseconds. It is therefore important

that the power supply circuit contains a large capacitor which can

buffer that peek. The tuxgraphics ethernet board has already a number

of capacitors on board to make the peek more round but it still needs

a good external power source.

If you use a ready made switched power supply (as I did) then it is often unknown how

big the internal capacitors are. It is however very easy to test if the

capacitors are big enough:

Click several times the reload button in the web browser

and observe the temperature

readings. If the temperature values are changing all the time

then the power breaks down so much that the sensor board is influenced

by that. Just add a 1000uF capacitor in this case. Note that the pressure

sensor may fluctuate behind the decimal point. That is normal.

The main power design guidelines are therefore:

- Use a big capacitor (1000uF or more) in power circuit

- Avoid ground loops.

- Keep the wires short.

Converting voltages into "weather" readings

The temperature and air pressure readings arrive now on the avr

webserver as ADC reading. Numbers between 0 and 1023. The main

task of the software is now to convert this back into Celsius,

Fahrenheit or hPa and display it on a web page.

The LM335 temperature sensor produces 10mV/K (mV/K=

Milli_Volt/Kelvin). This is however only valid if the measurements

are taken with very high impedance. The impedance of our

differential amplifiers is 91K + 68K = 159K. The datasheet of

the LM335 does unfortunately not explain what will happen but

the voltage drop at a load of 159K should be very low given

that the impedance of the LM335 must be much less than 4.7K

(the pull-up to 5V). The amplification factor of the amplifier

is 91K/68K=1.338. The ADC produces a reading of 1024/1100 per

mV. In other words we get 12 ADC-steps per Kelvin:

10mV/K * 91K/68K * 1024/1100mv = 12.4 ADCsteps/K

The whole conversion can be fine tuned in the file config.h

(see source code download at the end of this article) and the

parameters KELVINPERADC0 and KELVINPERADC1 correspond to this

ADCsteps/K times 10. If neither the resistors nor the LM335 had

any tolerances then both KELVINPERADC0 and KELVINPERADC1 should

have 124. The file config.h contains in the temperature section

also the parameters OFFSET1 and OFFSET0. This is an offset to

0'C. The offset may change if the supply voltage is not exactly 5V (

the reference for the differential amp. changes then).

If you don't have a very accurate reference to calibrate the

temperature readings then I suggest to not change too much in

config.h It will be almost correct. What you can do is this:

Take some tape and stick both LM335 together. Wait 10min for

them to have exactly the same temperature then check what the

readings are. Now change KELVINPERADC2 and KELVINPERADC1 such

that the two temperature readings are the same for both sensors

and meet in the middle (increase the one which is too low and

the lower the one which is too high).

The air pressure sensors is just slightly more complicated.

First of all you should know that the air pressure changes

maybe by 1-5 hPa over the day. A weather dependent high

pressure zone might have 1030 hPa and a low pressure zone 1010

hPa. The air pressure is however much more dependent on the

hight above sea level. If you change your altitude by just 100m

then the pressure will change by 12 hPa. It is therefore

a convention that all weather stations report a pressure reading

normalized to sea level. The pressure offset to sea level is:

Poffset=1013hPa * (1-(1- 0.0065 * h/288)^5.255)

h=height above sea level.

The formula can be derived from the Barometric formula.

See http://en.wikipedia.org/wiki/Atmospheric_pressure

and http://en.wikipedia.org/wiki/Barometric_formula

The file config.h contain the parameter SEALEVELOFFSET which is

exactly this Poffset times 10 rounded to the next integer

value. Here is a javascript calculator to calculate the

SEALEVELOFFSET parameter for you:

Some encyclopedias and local maps will usually show at what hight above

sea level your town is. If you live in a high building then you need

to take this also into consideration.

The reference voltage for the differential amplifier depends on

R27 which is to be selected dependent on your altitude. Since

most people on earth live near sea level you will either use

5.6K (0-400m) or 18K (400-1000m) for R27.

The reference voltage (the voltage over R23) is calculated as

follows:

Refvoltage=5V * 5.6K/( 5.6K + 1/(1/R27 + 1/2.7K))

The differential amplifier amplifies the difference between

this reference voltage and the voltage from the air pressure

sensor. Now we just need a formula that gives us the air

pressure for a given output voltage of the air pressure sensor

and we are almost done with the calculations:

Vout=5V* ((0.0009*P/hPa)-0.095)+Error

Vout= output voltage in V at the MPX4115A pressure sensor

P=air pressure in hPa

Error=an error term caused by tolerances during the manufacturing

of the MPX4115A.

Therefore P is:

P=((Vout+Error)/5V+0.095)1111.11 hPa

P=(Vout+Error)*1/V*222.222 hPa +105.555 hPa

If we convert Vout into ADC steps and included also

the error term there then we get:

P=(adc/1024*1.1/Gain +Refvoltage/V)*222.222 hPa +105.555 hPa

The gain of the differential amplifier is 100/47=2.1

We insert this into the equation:

adc *1.1 * 222.222 hPa

P = ------------------------ + (222.222 *Refvoltage)hPa/V + 105.555hPa

1024 * 2.1

adc *10

P = --------- hPa + (222.222 *Refvoltage)hPa/V + 105.555hPa

87.8

In the config.h file I have included a REFTERM_A parameter which is

this term to the right of the above equation:

adc *10

P = --------- hPa + (REFTERM_A/10) hPa

87.8

Now that is a lot of math but don't worry the software is

already written. If you just want to use it then measure the

voltage above R23 or use the above javascript calculator and

then calculate REFTERM_A with the following calculator. Insert

REFTERM_A in the config.h file and you are done.

Something we have now discarded a bit is the Error term in the

formula for the MPX4115A pressure sensor. It is part of the adc

variable in the above formulas. In the config.h file I have

included a parameter called ERROR_A. If you have no reference

available then just set it to zero. If you have some weather

station readings from a station near by then you use that to

tune the Error term. Here are e.g some weather forecasts

including readings from the current day:

The software

Just download the eth_rem_dev_weatherstatio-x.y.tar.gz file

at the end of this article. Unpack it (tar zxvf

eth_rem_dev_weatherstatio-*). Most of the above formulas are

implemented in the file analog.c but the configuration is done

via the header file config.h. Edit also the main.c file and

insert the IP address you would like to use. Compile the software

with the command "make". After that just download the

eth_rem_dev_weather.hex into the microcontroller:

avrdude -p m88 -c stk500v2 -e -B 2 -U flash:w:eth_rem_dev_weather.hex

That's all!

Point your web browser to the selected IP address

(e.g htpp://10.0.0.25 ) and see what the weather will be like.

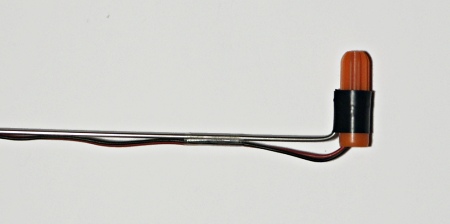

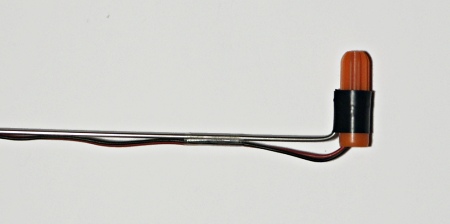

Mounting the out door sensor

It is probably possible to seal the LM335 out-door sensor in

resin or glue to make it water proof. I personally don't

believe in such methods because one day some water will get in,

stay there and corrode the wire. It is better to just

shield it against heavy rain and otherwise make sure that it

can always dry again. A half open tube is very good for that. I

use a felt-tip cap:

The out-door sensor. Protected by a felt-tip cap.

The weather station as seen from firefox

A screen shot of mozilla firefox

High air pressure (above 1020hPa) is generally an indication for coming good

weather. Low pressure may bring rain.

If you see the air pressure increasing in the evening then it is a good

indication that there will be no more rain the next day.

The final circuit without LCD

The whole weather station circuit is very modular. You can use it with and without air

pressure sensor and the LCD display is also optional. Below is

a photo of the weather station without LCD display.

![[weather station circuit without LCD]](../../common/images2/article07041/weatherstation_no_lcd.jpg)

The bare Ethernet weather station circuit without LCD

The software made for the weather station with LCD

(eth_rem_dev_weatherstation-3.X) will also run

on the one without but I recommend to use eth_rem_dev_weatherstation-2.X

which does not use the digital IO port of the ethernet card and

is made for the weather station without LCD.

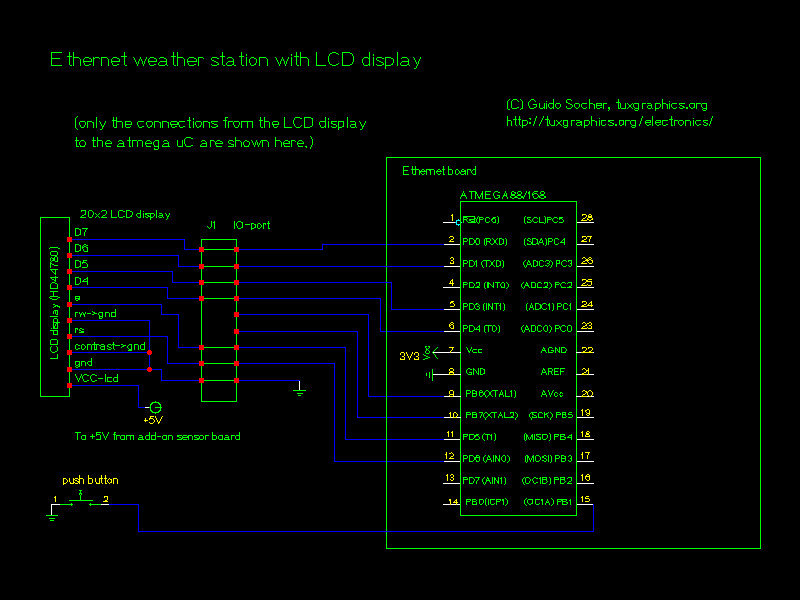

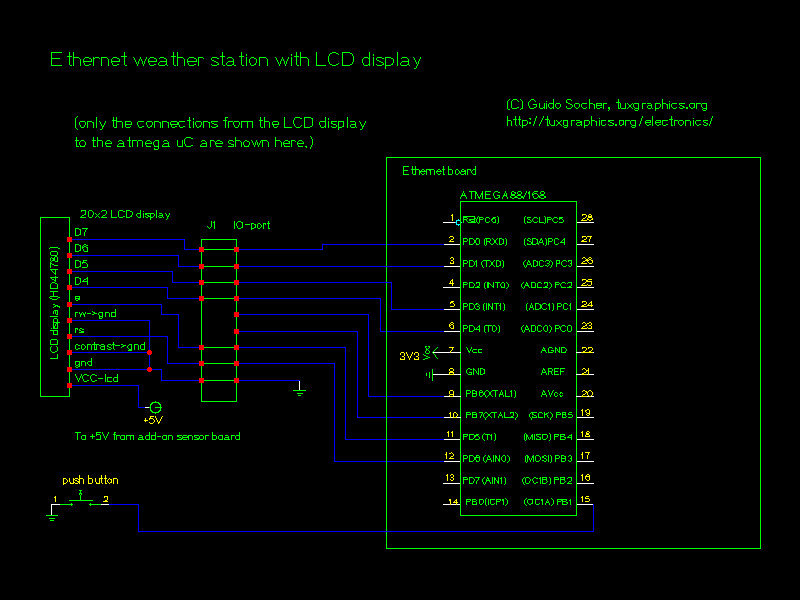

Adding a LCD display

Just connect the LCD display on the exact same pins as in the previous

article "A LCD display with ethernet interface":

Click on the picture to get a high resolution PDF

drawing.

I have decided to connect the button to change the display

on PB1 because we don't need the LED which is normally connected

there. The button toggles the display units from 'C to 'F.

Here some photos of the Ethernet weather station which I build. It is

very small. On the back you just connect power, ethernet and the out-door

sensor.

![[weather station circuit with LCD]](../../common/images2/article07041/eth_weather_st_lcd_txt.jpg)

Ethernet weather station circuit without LCD

![[weather station circuit with LCD, top view]](../../common/images2/article07041/eth_weather_st_lcd_topview.jpg)

Ethernet weather station circuit with LCD, top view

On the software side there really nothing new here. We just

display the temperature and air pressure readings locally on the lcd

display. A small "+" sign in the lower right corner of the display comes

and goes to let any human person know that everything is still working and

the display is not frozen (temperature and air pressure change very slowly

during the day). The lcd driver code

is in the files lcd.c, lcd.h and lcd_hw.h.

Feed a database

The web server displays a web page. That page can not only be

evaluated by humans but also by scripts. You might e.g collect

the readings every few hours and save it in a file or database.

The the command line web browser w3m

(http://sourceforge.net/projects/w3m/) can be used for that.

w3m -dump "http://10.0.0.25/"

That's all you need to get machine readable readings. You can

re-direct the output to a file and then process that file. Very

easy.

Download and links

© Guido Socher, tuxgraphics.org

2007-05-17, generated by tuxgrparser version 2.55

![[Illustration]](../../common/images2/article07041/eth_weather_st_lcd_title.jpg)

![[weather station circuit without LCD]](../../common/images2/article07041/weatherstation_no_lcd.jpg)

![[weather station circuit with LCD]](../../common/images2/article07041/eth_weather_st_lcd_txt.jpg)

![[weather station circuit with LCD, top view]](../../common/images2/article07041/eth_weather_st_lcd_topview.jpg)