Pool timer

![[Illustration]](../../common/images2/article11081/title.jpg)

Abstract:

We build a timer and a temperature sensor for a swimming pool and by

combining the two into one unit we can simplify the installation of the temperature sensor.

This project is based on the 24h timer, a timer that repeats its program daily and can be

programed very easily via a web-interface.

It can be used from any smartphone or PC with a javascript

capable web browser.

The pumps as used in swimming pools consume a lot of

electricity. This is not because of the efficiency of

the pump but because water is heavy and the pump requires

the energy for the physical work to move the water mass

around at high speed. It's a waste of energy to run

the pump all day. To keep the water clean it is more

than enough to run it for about 4-6 hours per day distributed

over the day.

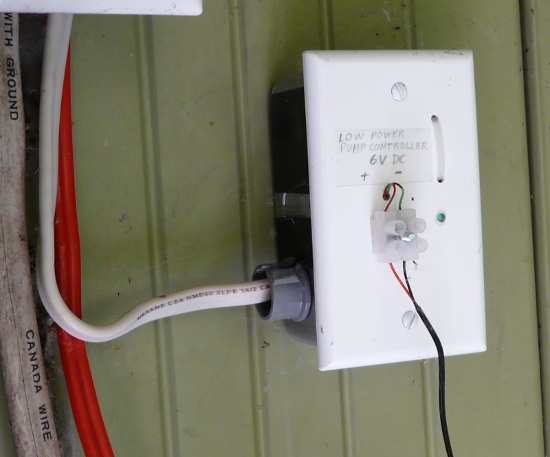

This web-based 24h timer is designed to control a swimming pool pump

and measure air and water temperature. It

plots the temperature history as as bar graphs. By combining the timer for the pump

and the temperature sensors into one unit we have more flexibility

in installing the temperature sensor. There is no need for

a sensor in the pool water and

the whole unit can be conveniently installed in a shed near the pump.

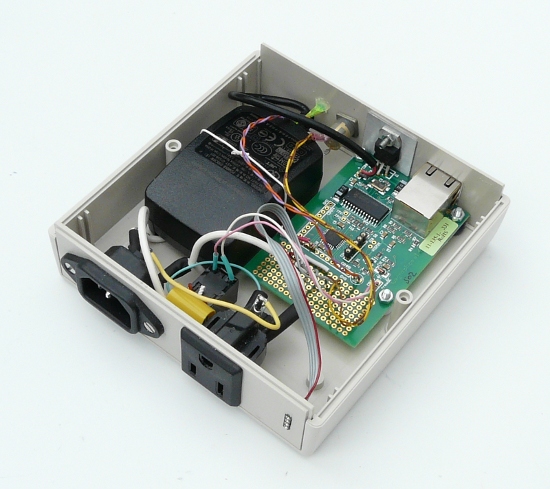

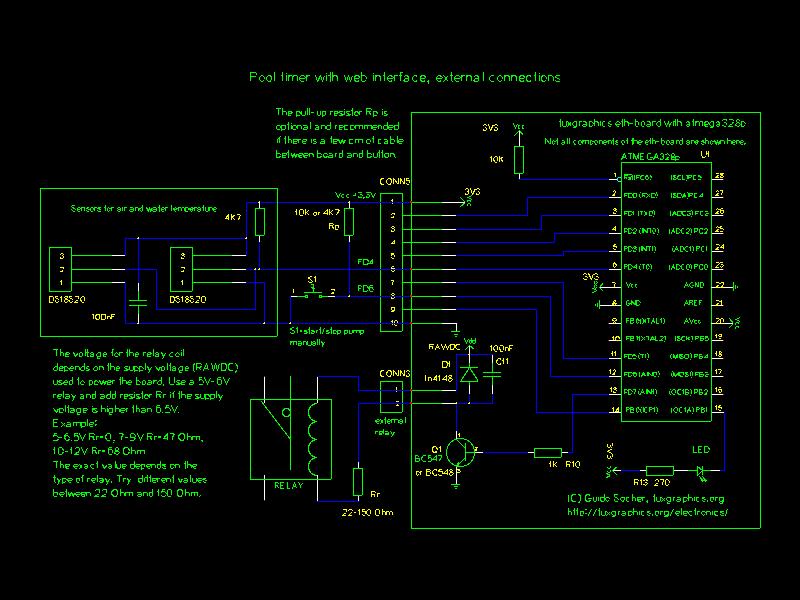

The base hardware is the tuxgraphics ethernet board. The software

loaded into the board provides a web server with hardware control functions.

You can operate this pool timer with

a few mouse clicks for your PC or smartphone.

_________________ _________________ _________________

|

![[Illustration]](../../common/images2/article11081/title.jpg)